How a Large Brick Manufacturer Will Save 12,000+ Tonnes of Carbon Per Year

Industry

Manufacturing

Our customer has some of the most ambitious plans and growth-focused investment strategies in the brick industry.

They are currently investing £140 million to significantly improve efficiency, maximise production capacity, and minimise the environmental impact of their brick production at three key manufacturing sites.

To achieve this, having the most forward-thinking, innovative partners will be key.

In partnership with QiO, one of the UK's largest brick manufacturers has immediately reduced their carbon emissions to meet stringent environmental standards and combat rising energy prices. Their carbon neutral commitments will see them reduce overall emissions by 32% by the end of the decade and achieve net zero by 2050; the carbon savings from their partnership with QiO will go a long way towards achieving these goals.

Short Time to Value

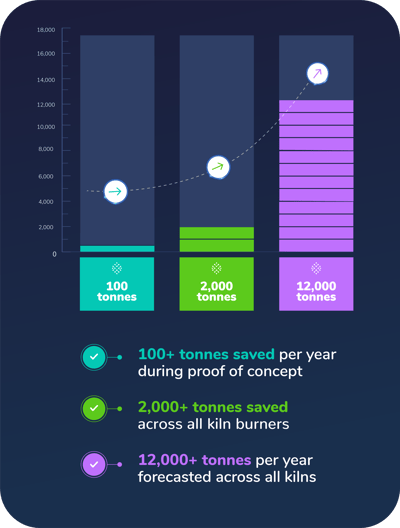

The pilot implementation alone delivered immediate carbon savings of 100+ tonnes per year, which will scale to over 2,000 tonnes across the whole kiln. This is thanks to QiO’s autonomous control platform, which continuously monitors zone temperatures throughout the kiln and automatically adjusts gas flow to the burners via the PLC/SCADA system.

This enables precise control over ramp rates and minimises temperature overshooting, helping to optimise gas usage without affecting product quality or consistency.

Read the full story

Enhancing Kiln Efficiency Amid Rising Energy Costs

Brick manufacturing is inherently energy-intensive, requiring precise temperature management within kilns to maintain product quality.

Traditionally, this heavily relies on skilled manual oversight, which, despite being effective, presents opportunities for further efficiency gains. Although kiln temperature is controlled by a PLC, operators have limited options to frequently or broadly adjust temperatures across multiple setpoints. This causes slight delays when responding to temperature changes, resulting in inefficient gas usage.

Volatile natural gas prices mean that every percentage point saved in kiln energy consumption translates directly into improved profitability. QiO's real-time autonomous control platform delivers exactly these savings without compromising quality.

QiO’s Solution: Real-Time Autonomous Control Platform

QiO's real-time autonomous control platform is precision-tailored to the brick manufacturer's precise kiln operations.

It dynamically manages setpoints and adjusts temperatures in real-time, maintaining precise temperatures at each kiln stage while minimising gas flow. It also considers brick type, furnace conditions, and pre-production factors to fine-tune recommendations, reducing variability and ensuring consistent application without compromising quality.

The solution went from pilot to measurable energy and cost savings in just weeks, providing them with immediate ROI and carbon reduction. During the pilot alone, QiO’s system automatically made over 70,000 precise control adjustments, ensuring optimal temperature management around the clock.

Following successful implementation at the pilot site, they are now actively progressing towards deploying QiO’s solution across additional sites, further scaling the benefits.

Outcomes: Significant Carbon and Cost Reduction and Empowered Teams

The deployment of QiO’s real-time optimisation product quickly translated into significant natural gas savings. Precision temperature management ensured consistently high-quality brick production, eliminating the possibility of temperature overshoots. This drastically reduced their carbon footprint.

They also gained comprehensive, real-time insights into kiln operations through automated reporting. This visibility supports broader enterprise-wide energy strategies, enabling data-driven decisions on efficiency initiatives across multiple manufacturing sites, as QiO's product is designed with scalability in mind.

Strategic Impact: Positioning Them for a Sustainable Future

The brick manufacturer saw considerable carbon savings of over 100 tonnes per year during pilot phase, which will scale to over 2,000 tonnes across their entire kiln. As they scale this across six sites, they are forecast to save over 12,000 tonnes of carbon year-on-year, making a considerable dent towards their carbon neutral goals.

As an additional benefit, they also saw kiln energy savings of between 1.6% and 2.2%, depending on brick type. As they expand this solution across additional burners and sites over the next five years, they expect to achieve total energy savings of approximately 10–11%.

Their collaboration with QiO serves as a compelling blueprint for manufacturers seeking to reduce energy costs, optimise processes, and enhance precision control, driving both operational efficiency and sustainability.